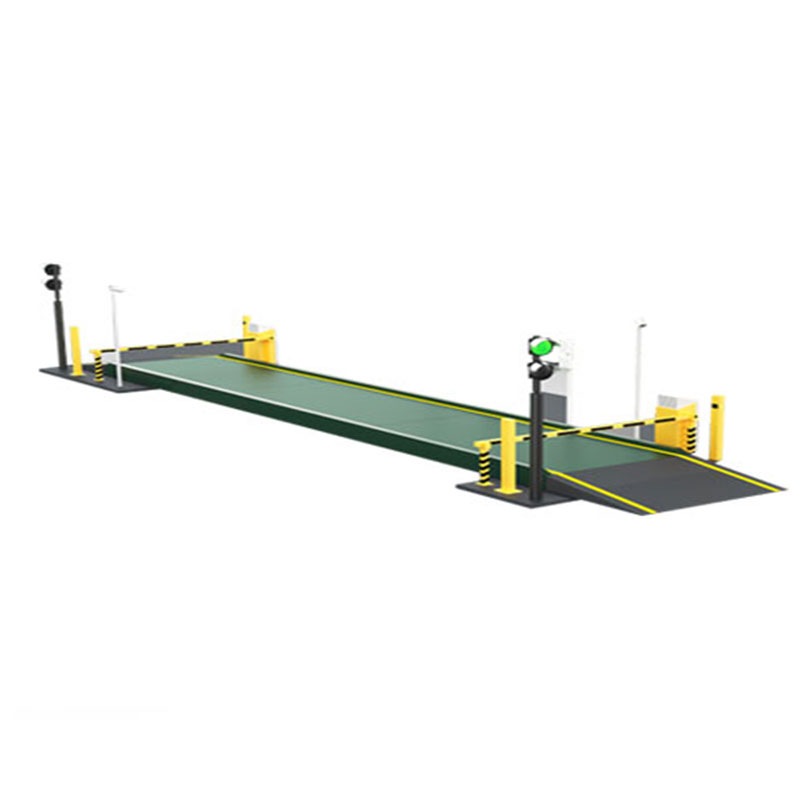

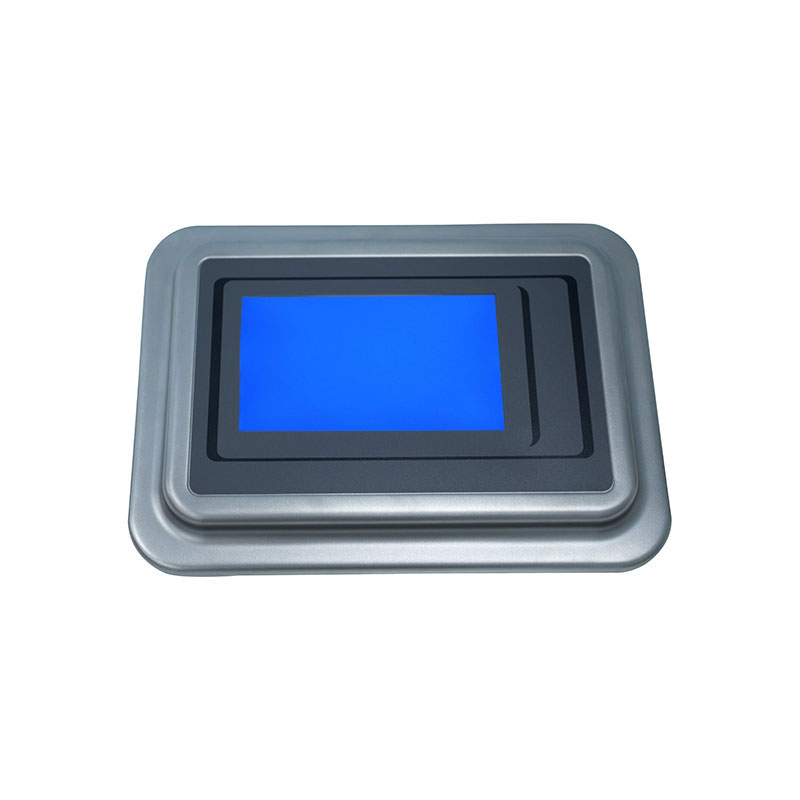

Weighing instrument

category:weighing instrument

Brand:WEIGHT WORTH

Phone:400-030-7767

brief introduction:Weighing instrument is also called weighing display control instrument. It is an electronic equipment that converts the signal of weighing sensor (or through weight transmitter) to digital display of weight, and can store, count and print w......

Weighing instrument is also called weighing display control instrument. It is an electronic equipment that converts the signal of weighing sensor (or through weight transmitter) to digital display of weight, and can store, count and print weight data. It is commonly used in automatic batching and weighing in industrial and agricultural production to improve production efficiency.

Weighing instrument installation: generally, clean, dry, ventilated and suitable temperature environment should be selected to place the instrument. The position of the instrument should be fixed, and it should not be moved frequently, otherwise the internal lead of the signal cable plug may fall off and cause failure.

Power supply of weighing instrument: most weighing instruments use 220 V AC power supply, and the allowable voltage range is 187-242 v. After changing the power line, remember to measure whether the voltage meets the requirements before powering on the instrument. If the 380 V power supply is connected to the instrument by mistake, it may cause damage. The voltage regulator with good performance (such as CW AC parameter regulator) should be equipped to ensure the normal use of the instrument in the case of large fluctuation of power supply voltage. Do not use the same power socket with strong interference source (such as motor, electric bell, fluorescent lamp) to avoid the instability of instrument display value. Some instruments (such as hawk meter) are both AC and DC. It should be noted that battery leakage will damage the instrument when using dry battery. When the battery is not used for power supply for a long time, the battery should be taken out.

Grounding of weighing instrument: weighing instrument shall be connected with independent and good grounding wire (grounding resistance < 4 ohm, grounding lead shall be as short as possible). The grounding wire has dual functions: it not only can protect the personal safety of operators, but also has important anti-interference function, which can ensure the stable operation of the instrument. The ground wire is connected to the power socket of the instrument. If the instrument ground wire is connected to the public strong current protection ground wire, it may cause power interference to the instrument and make the instrument display value fluctuate. Regularly check whether the ground connection points are in good contact. Because after a long period of time, the connection points will produce oxidation, corrosion and other conditions, which will make the instrument actually not work.

Sunscreen of weighing instrument: avoid direct sunlight on the black shell of the instrument, otherwise the instrument may be damaged if the working environment exceeds the rated temperature range.

Weighing instrument waterproof: in general, the humidity of instrument working environment can reach 95%, but it is stipulated that condensation is not allowed. Except for the special stainless steel case with waterproof function.

Anti corrosion of weighing instrument: corrosive substance shall not penetrate into the instrument, otherwise it will corrode the components on the circuit board and the circuit board itself, and the instrument may be scrapped for a long time. Even if the instrument with anti-corrosion function, if not tightly sealed, will also have the same result.

Lightning protection of weighing instrument: electronic weighing instrument belongs to weak current system, which is easy to be damaged by lightning. Lightning mainly enters the instrument from two aspects: from the power line and from the weighing platform through the signal cable. In normal weather, the operator can only operate the power switch, but in case of close lightning strike, the instrument power plug and the signal cable plug of the scale platform must be pulled out. It is better to take lightning protection measures, such as adding surge protection device in the instrument power circuit.

Anti strong current of weighing instrument: if the fire line of power supply above 220 V is accidentally set up on the weighing platform or the platform is used as the ground wire, the instrument may be damaged by welding on the platform.

Cleaning of weighing instrument: in the industrial environment, there will be dust or pollution on the instrument shell, which must be cleaned with wet cloth in case of power failure. But pay attention not to use alcohol and other solvents to wipe the display window, which will make the light transmission performance bad, display module burning.

Anti static of weighing instrument: once the instrument is damaged, it should be sent for repair. In order to speed up the transmission, some units like to remove the PCB board of the instrument and send it by express mail, which leads to an anti-static problem. When taking the PCB board, hold the four corners of the board, and do not touch the place with integrated block pins by hand. Because it is easy for static electricity to damage the integrated block. The removed PCB board should be put into the shielding bag immediately. If there is no shielding bag, ordinary newspaper can be used to wrap it. If you put the board on the table with high insulation, it may damage the PCB board. When you receive the repaired PCB board and need to install the instrument again, you should also pay attention to anti-static.

Maintenance of weighing instrument:

1. Sunscreen: avoid direct sunlight on the black shell of the instrument, otherwise the instrument may be damaged if the working environment exceeds the rated temperature range.

2. Waterproof: in general, the humidity of instrument working environment can reach 95%, but it is stipulated that condensation is not allowed. Except for the special stainless steel case with waterproof function.

3. Anti corrosion: corrosive substances shall not seep into the instrument, otherwise it will corrode the components on the circuit board and the circuit board itself, and the instrument may be scrapped over a long period of time. Even if the instrument with anti-corrosion function, if not tightly sealed, will also have the same result.

4. Lightning protection: electronic weighing instrument belongs to weak current system, which is easy to be damaged by lightning. Lightning mainly enters the instrument from two aspects: from the power line and from the weighing platform through the signal cable. In normal weather, the operator can only operate the power switch, but in case of close lightning strike, the instrument power plug and the signal cable plug of the scale platform must be pulled out. It is better to take lightning protection measures, such as adding surge protection device in the instrument power circuit.

5. Anti strong current: if the fire line of power supply above 220 V is accidentally set up on the weighing platform or the platform is used as the ground wire, the instrument may be damaged by welding on the platform

remind:Due to the large number of product models and specifications, and support the customization of size, function configuration and other requirements, all product prices, configurations and so on are subject to the electronic negotiation and the actual scheme!

English

English Chinese

Chinese